This is a minor renovation assignment that was conducted at our flat in the middle of last year (2011) and is uploaded on my new blog recently.

We hope that all readers & new home owners or home owners-to-be would find this review useful!

Scenario:

When we first bought the flat 10 years ago, we felt that it was a marvelous concept that the previous owners brought down the wall between the MBR & the common room next door.

As such, we bought over a flat where the MBR and the common room were amalgamated to form one super huge MBR.

However, after 10 years down the road, we had aged and there was also a paradigm shift in our mentality.

We felt that it was so silly & impractical of us to have bought such a flat. We paid tonnes of $ for a 5-room flat and only to be saddled with just 2 bedrooms (excluding a studyroom which had tempered glass sliding doors & couldn't be considered as a bedroom in proper). We might as well have bought a 3-room flat instead during our younger days as a newly wed couple! :bangwall:

Many who had were such buyers like us, had difficulty selling off flats with such layouts eventually. So we had decided to put back both rooms so that they could be used independent of each other.

Interviewing contractors & IDs:

We had spoken to several IDs and realised in no time that some of them do not take up such assignments because we did not require any interior designing or the job was not significant enough to beef up their profit margins.

And that all we required was just structural alteration works, which left out the presence of an ID in our equation.

So we figured out that the best bet is to approach the contractors directly and we interviewed more than 20, including those who were highly recommended over RT forum.

Finalising our selection of a cement specialist/ contractor:

Finally, we shortlisted a cement work specialist (Ah Cheong) who had been introduced to us by our network of friends.

He specialises in demolishing of walls, erection of walls, tiling works, plastering, etc i.e. any renovation works that involves cement.

Both his tiler and himself visited us sometime towards the last few months of last year - if I didn't recall wrongly, it was in October 2010. He was unable to proceed in taking on any new assignments as his hands were so full that the earliest we could get into the queue was after the Chinese New Year period in year 2011!

He had addressed ALL our concerns and had also mentioned the following which we weren't aware of:

a) the demolishing would cause the existing tiling and skirting to crack because of the impact of knocking.

b) measurements would be taken up to protect our flooring during the renovation works & to minimise tiling cracks.

c) red bricks are not allowed because our prefabricated flat would be unable to withstand the weight of having red bricks being piled ontop of hollow block walls. We were shocked because we had the idea that HDB flats were built of red bricks but he had mentioned that the exterior is but not the interior, which are built of hollow blocks, most probabbly the 2.5" type.

He gave us an option of using hollow blocks with either 2.5" or 4" thickness. We chose 4" for supposedly better accoustic properties i.e. privacy in blocking out of noise between the 2 bedrooms.

A quotation was emailed to us on a separate ocassion after he had worked out details of our assignment, which included an extension of cement platforms in our kitchen. It will cater to the DIY installation of our IKEA kitchen cabinets later on.

In view of other errands in the flat which had to be executed before the renovation e.g. fengshui audit, termination of telephone points, rewiring in both bedrooms, etc, there were delays in engaging him.

By the time we tried to get hold of him, we were almost feeling disappointed because his work schedule was so packed that... we were almost left out of the queue :( Not his fault because his business was so good that we could see from his appearance that he was overworked & totally worn out.

MBR : Its amalgamated appearance, i.e. before reno

This is an awful photograph of a section of the super-huge MBR before its reinstatement to its original HDB layout - it's too huge to be captured in the entire photograph:

The photo was taken in the afternoon and with its eastern facing, the lighting wasn't sufficient during that hour of the day; so it looked awful in the photo. Even the beautiful flooring had a "dirty" look.

So for those of you out there who had beautifully renovated designer homes, I could understand if u had a jaw breaking experience after looking at my threads with such a photograph! :jawdrop:

hehehehehe :P

Obtaining the approval of the HDB permit

The approval for HDB permit for this minor renovation was delayed too because our contractor, Ah Cheong assumed that the approval would be granted within 3 working days so he submitted on a Tuesday the week before the desired week for renovation.

The renovation was scheduled to take place on the following Monday (in April 2011) but we were shocked when he told us that the permit hasn't been granted yet.

Ah Cheong wanted to ferry us down to HDB branch office but I called the HDB branch office at about 9.15 AM to find out the status. And the technical officer had gone through the stack of mailers, but there were no traces of approval for our HDB permit yet.

He had assured us that it shouldn't be an issue because the HDB Architect required time to do the necessary before approving; he also promised us that he would contact me once he received the approval.

And it was really nice of him to keep track of the status for us. He called us up on the very same day in the afternoon at about 3.30pm to inform us that the approval had been granted and that the letter to us owners would be on its way out to the post office.

Getting ready for the BIG day :

- Laying Protection over our existing tiling; and

- Uploading Raw Materials

While we were waiting for the HDB approval to be granted on that Monday, whereby the reno was supposed to kickstart on but didn't materialise, Ah Cheong wasted no time in sending down his staff, whom we nicknamed "Ah-Bui" (becox he was really tall & plump but very young & hardworking) and another foreign worker to lay the ground work for the BIG day - which was to take place the following morning (after the approval was given on that very same afternoon).

But both my hubby & myself were genuinely fond of him (we have many nephews of his age) because he is a very quiet worker who goes about getting things done without uttering a word. Quiet, stable and systematic was how we would describe him; and we prefer quiet, diligent workers to those talkative, lazy bones.

That's a photo of "Ah Bui" :

Corrugated paper (brand new) of a certain thickness had been laid, starting from the groove of our door step, all the way into our bedrooms. It was also extended like a red carpet that ran from the entrance all the way to the passage way where the wall is to be demolished to recreate a door entrance to the new bedroom (which used to be a common room next to the MBR from HDB's original floor plan).

Photo of a roll of corrugated paper:

Photo of one of the foreign workers putting the corrugated paper in place at the entrance of our MBR:

Photo of a long carpet of corrugated paper taken from outside out kitchen entrance

Photos of "Ah Bui" managing the taping of corrugated paper inside our MBR:

Getting ready for the BIG day :

- Laying Protection over our existing tiling; and

- Uploading Raw Materials

Now you can see why we call him "Ah Bui" just by

looking at this photo

And relatively thin sheets of wooden boards (brand

new) were brought in and placed at the locations where cement mixture is to be

prepared and where the demolishing would take place.

"Ah Bui" taping the wooden board to the MBR's

floor:

Placing the wooden board where the debris would accumulate

when demolishing of part of the wall takes place the following day:

Then, they started bringing in the raw materials &

equipment; which could be seen in the photos uploaded as below.

4" thick hollow blocks, sacks of cement, plasters,

sand, etc.

Uploading the hollow blocks inside our MBR:

Photo of gunny sacks for containing debris, huge red spade

and a red hammer weighing tonnes (for demolishing the wall to restore entrance

to a door):

Photo of the hardworking foreign worker sweeping the

corrugated carpet after uploading all the materials in our MBR:

All neat & fully equipped for the BIG DAY the next

day! :horse:

The arrival of the BIG DAY!

DAY 1

Our contractor, Ah Cheong, rushed over from another on-going

project to our flat in the morning and pasted the HDB renovation permit outside

our flat.

Without further delay, he started demolishing the wall with

the red hammer that I couldn't even lift up!

The noise was deafening by our standards. We stood at a distance while he started

knocking just above the skirting.

He was poised as if he was playing golf, but what a

dangerously heavy "golf" club he was using!

And soon, a small hole was seen as the debris started

falling onto the wooden board that was laid on the floor inside the

common-room-to-be.

As he went on knocking the wall, the hole got bigger as more

debris accumulated on the ground which was protected by thin sheets of wooden

board.

The demolishing was conducted bottom up and he switched from

the golfing posture to a top-hacking gear as you could see in the photos below:

A pile of debris autographed by the "killer"

hammer which I couldn't lift up, no matter how hard I tried to. I wondered how Ah Cheong managed to lift it

up!

Now, both my hubby & myself knew where Ah Cheong got his

gorgeous biceps from! he-he-he-he-he...

We observed Ah Cheong running to the common-room-to-be

through the MBR's door throughout the demolishing exercise.

Not sure what he was looking out for. But, we saw him gathering up the pile of

debris - as a buffer to more debris as the demolishing take place?? Some were thrown into the gunny sack but

some were stacked onto the existing pile of debris.

We were so overwhelmed by the amount of dust fogging the

living room that we could only guess what he was doing. And my hubby also reminded me to suppress my

talkative genes so that Ah Cheong could conserve his energy for demolishing the

wall.

Jux look at the amount of dust flying in our flat by the

time he completed the demolishing of the wall to create the entrance to our new

common-room-to-be!!! :(

I hope that the photo has clearly captured the foggy

atmosphere in our living room. It was a

real nightmare becox we're still staying in the flat while this is

happening!

Removal of Debris

After the foggy episode with dust arising from the

demolishing of walls, there is another sand storm coming our way!

But before I move on to tell about more about they continued

to stir up a sand storm, Ah Cheong took the lead in sweeping up the debris that

flew off track from the huge pile of debris.

He then delegated the removal of debris to another foreign worker and

"Ah Bui".

Chiseling

I'll like to mention here that becox Ah Cheong had

demolished the wall by hitting at the area ABOVE the skirting running at the

bottom of the wall (adjacent to floor tiles), he had used a chisel & hammer

to carefully knock off the skirting lining surrounding the demolished work site,

that's if they had signs of cracks, etc.

You could see here in these photographs that he was also

making an effort to neaten the uneven flooring arising from the new

entrance. Raw of course with seasoned

cement that was buried under the fabricated wall for the past 15 years!

We were anticipating cracked tiles & damaged skirtings

but only the sides of flanking the new doorway had ceramic skirtings that

chipped off! The damage was minimal and

to us, negligible. What a pleasant

surprise!

Excellent demolishing work!

When we first met Ah Cheong for a site visit at our flat, he

did mention that it is not necessary for fabricated hollow block walls to be

sitting on the ground with existing ceramic tiles dug up.

However, we were "kia-su" (a hokkien slang for not

wanting to lose out) and we're not sure since when we acquired the idea that

ceramic tiles were slippery and the wall wouldn't hold well. Likely to be through a couple of

construction firms who were building bungalows.

Even though Ah Cheong assured us that the wall wouldn't

collapse becox of its weight, we still wanted to create more friction on the

ground so that the walls would be built on a extra strong & stable

"foundation".

So we stuck on to our own idea and were billed for it of

course

The worker who was given this assignment to cut out the

ceramic tiles and build the walls was Ah Ming.

He stepped into the picture while Ah Cheong was chiseling the rough

edges of the new doorway after the demolishing was completed.

And like Ah Cheong and "Ah-Bui", he took extra

care of our ceramic tiling and even our electrical switches.

Sand-STORM :

And with the adamant decision to have the tiles cut prior to

building the hollow block walls, a SAND STORM was inevitable! :(

Ah Ming flipped up one of the pieces of wooden board in our

new common room and used that as a make-shift door to block out as much dust

which he warned us, would be terrible while he cuts out sections of the ceramic

tiles where the new wall would be built on.

During the lunch break, we heard him forcing out the dust

really hard from his throat - no phlgem was heard but my hubby said that he was

forcing out the dust. And we didn't

blame him for cleaning his nose at the emergency staircase after he ate his

lunch.

Fabricating of (hollow-block) Walls

After Ah Ming extracted sections of the existing ceramic

tiles, we took pictures of his beautiful handiwork and if you refer to the

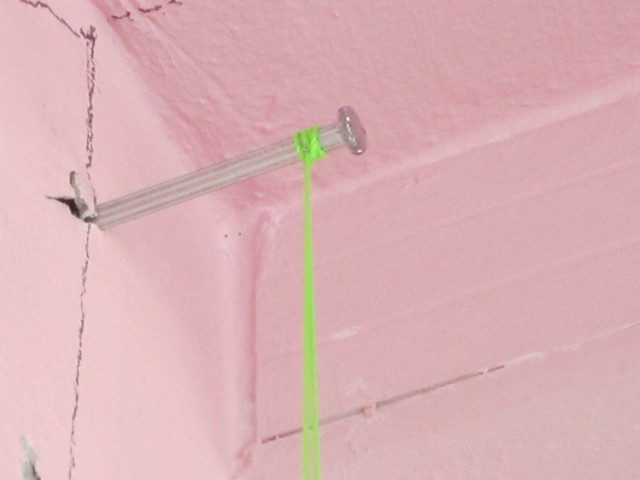

photographs below, you would notice that he had put up green strings held on by

nails at all 4 corners where the new wall would be constructed at.

Ah Ming explained that it was to ensure that the walls are

upright and straight while he built them up.

He had also been very considerate in wrapping our power

points with corrugated paper to prevent cement from staining or choking them

up.

After setting up the green strings that are held in place by

nails on the sides of the walls, Ah Ming started to construct new walls with

the 4" hollow blocks.

Once the hollow block walls are completely stacked up with

cement, Ah Ming started to apply the first coat of cement as shown in the photo

below:

After a first layer of cement had been applied very

generously, Ah Ming used an aluminium or wooden "stick" with a flat

base to scale down the cement.

We observed that as he did that, some of the impurities e.g.

small pepples started falling off, which left holes in the cemented walls.

Another coat of cement has been applied generously over the

first layer.

Those "holes" or "gaps" left by the

pepples or stones which were taken out during the fist scaling process were

also covered with this second layer of cement.

Then, Ah Ming repeated the scaling process to smoothen the

cemented wall.

This scaling process is then followed by cleaning off any

cement staining the beams and existing wall with a damp sponge.

It was time for Ah Ming to knock off by the time he

completed applying 2 layers of cement on one side of the hollow blocked wall.

However, we were pleasantly surprised that Ah Ming had taken

the initiative to clean up the MBR.

We witnessed how tough his manual job was throughout the day

and told him that he need not clean up since reno work is still in progress.

However, he insisted on cleaning up the room before he

packed up and left.

He had explained to us that Ah Cheong & all the team

members would always make an effort to clean up "the mess" for owners

(before calling it a day) when they are living in while the renovation is

on-going.

And just take a look at how neatly packed the MBR is after

he cleaned up the place! 5 stars for

him!

Post-script (DAY 1):

Ah Ming had 2 of these rods with a flat underbase for

scaling down freshly cemented walls.

One of which is made of wood and the other aluminium. He had explained to us that the wooden

version is no longer produced and cost alot more than that the aluminium

version.

However, nothing lasts foreover becox repeated scaling would

thing down the wood. So it is indeed a

precious antique to him. The aluminium

version could not be used forever too.

Both versions had lifespans.

DAY 2:

- Cementing hollow blocked walls (continuation)&

- Installation of (wooden) door frame

Ah Ming dropped in the following day (Day 2) at about 8.30AM

and continued stacking up the second wall with hollow blocks.

Then, we left him in the bedrooms to apply cement & do

scaling.

So there weren't as many wall-related photos to show for Day

2.

However, the wooden door frame for our newly created bedroom

had arrived.

And after lunch, he had dealt with the wooden frame by

hammering nails in a "zig-zag" fashion as shown in the photo below

prior to installation:

He said that this would ensure that the door frame is

strongly embedded into the cement. Have

a stronger grip onto the cement when applied on during the installation

process.

(I am so sorry that I had a loss of words to express this

process clearly. Found it tough to

describe the technical process.)

End of DAY 2...

Ah Ming told us that plastering would be done the following

day (DAY 3) because the walls would start cracking if they were applied on the

very same day as the first 2 layers of cement.

DAY 3:

- Plastering of walls

- Installation of Skirting

- Switching of doors

Plastering of walls

Ah Ming prepared the plaster and applied all over the newly

cemented walls as shown in the photo below.

DAY 3 (continued):

Skirting & tiling

The tiling supervisor, Mr Loh & his worker Ah Keong came

by at about 10AM in the morning.

In fact, Mr Loh dropped by in the early evening on DAY 2

before we called it a day. He came to

inspect the area that required skirting & tiling; and also, the cement

platforms in our kitchen which required both extension breadth-wise &

hacking length-wise.

And before he went off on DAY 2, he left a bag of white

plaster & some accessories in our MBR along side with the other raw

materials which Ah Ming had been using for constructing the hollow blocked

walls and installing the door frame.

Photos below show these 2 existing cement platforms in our

kitchen bearing red markings made by Ah Cheong to highlight to Mr Loh on what

needs to be done.

These platforms are conventionally used to accomodate

kitchen cabinets and the extension is necessary in accomodating to our IKEA

kitchen cabinet, which my hubby would be installing on his own later on.

Upon his arrival on DAY 3, Mr Loh wasted no time in

demolishing inches off one of the cement platforms becox extra space is

required for installing a double-tracked kitchen door.

The amount of dust that was stirred up was terrible. It was a SNOW storm! And it's a pity that I didn't have the

chance to take a photo of Mr Loh being covered in white dust! I was told by my hubby that he emerged from

the kitchen covered in white powder!

We were told that they couldn't continue until the dust

settled so by the time I returned with their lunch, my hubby had installed a

heavy-duty fan in the kitchen to disperse the white fog.

And Ah Keong sweeping up & tidying the rubble in our

kitchen before continuing with their assignment:

Photo shows Mr Loh taking off the skirting very carefully

from the existing cement platform (i.e. before the SNOW storm was done - forgot

to include this in my earlier thread):

The samurai expression that was inserted into the photo was

a candid gesture; all in the name of having fun but it reminded me very much of

Mr Loh's facial expression. A man

with a sense of black humour. hehehehe.

To be continued from where Ah Keong was seen sweeping up the

rubble in the last photo in my previous thread, he (Ah Keong) placed 2 wooden

planks or were they aluminium (?? not sure) adjacent to each other against the

newly modified platform and started filling the "gap" or

"slot" with cement.

After the "slot" was fully packed with cement, the

2 wooden planks were removed as shown in the photo below:

We were lucky that the previous owners had left us plenty of

spare kitchen (bathroom) tiles given by HDB when they first bought the

flat. At least, they came into use for

this ocassion.

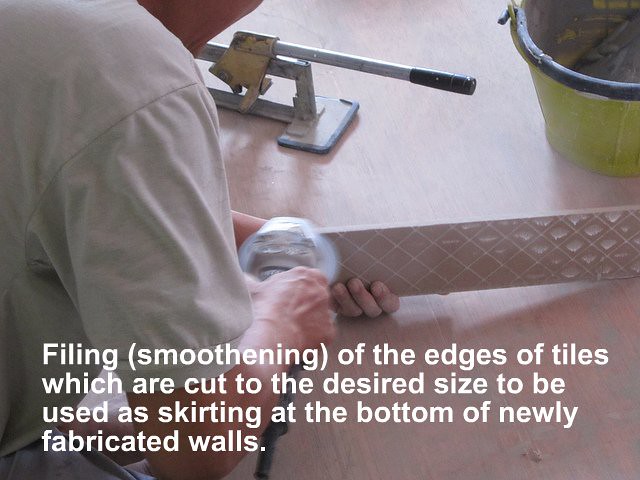

We had observed that Ah Keong had used a cutter to cut the

tile to a desired size (which in this case, is used as skirting lining the

edges of the newly extended cement platform).

An electrical gadget with a round blade as shown in the photo below was

used to "file" the edges of the tiles. Presumably to smoothen the edges. For a smooth finishing at the sides.

After sometime (cannot recall the exact duration), plaster

was being applied onto the top of the new cement blocks.

Then, Mr Loh used a damp sponge to clean up the excessive

cement lining our kitchen floor and parts of the skirtings.

Once the tiling & hacking works in our kitchen is

completed, the tiling team moved on to skirtings for our bedrooms.

Photos show the skirtings that need to be replaced on both

sides of the door entrance, from the interior and exterior of the newly

restored common bedroom:

They would also need to replace the tiles at the doorway

after demolishing the walls.

Photo shows a neatly chiselled gap between the existing

ceramic tiles where a wall used to sit on before Ah Cheong demolished it:

The final outcome of the tiling at the entrance of the newly

restored common bedroom as shown in the photo below:

A similar looking ceramic tile was bought by us after

searching through with many tile shops.

The new tiles had a similar print to our existing tiles but it has a

cream-coloured base and a pinkish undertone to it.

However, we are pretty happy with the outcome because the difference

between the existing tiles and new tiles weren't as obvious unless visitors

peer at them very carefully.

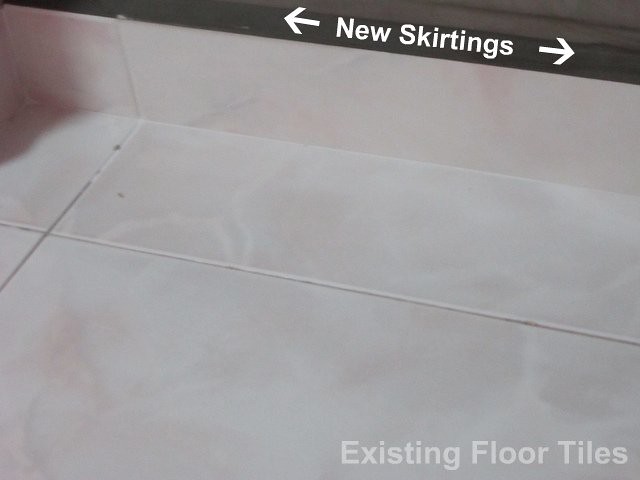

Photos of new skirtings...

The contrast is quite minimal when the new tiles were used

as skirtings. Because Ah Cheong had

done a very good job in demolishing the wall, none of the existing floor tiles

require replacement apart from the skirtings that were flanking both sides of

the new door frame as seen in the first 2 photos under post #29 of this thread.

In fact, we were left with 3 pieces of spare tiles!

The door installer was called in at the last stage of Ah

Cheong's renovation at our home to dismantle an existing HDB door from one of

our common bedrooms and re-install it in the newly restored common bedroom.

This same door company who was supposed to send down an

installer, provided the door frame earlier on.

However, it was quite a pain making this door company have their

installers keep to their appointments when we required a switching of door.

Anyways, the door installer reinstalled the door for us and

since he did a decent job when he finally arrived, it is case closed but we

would avoid using this door company in the near future.

As for the replacement of our bedroom door, we have decided

on Yontat Doors & will be starting a separate thread on this. So keep a look out for it if you are

interested in reading more about our shopping trip for wooden bedroom doors :)

Now that Ah Cheong has finally completed our

mini-renovation, he had arranged for his worker to drop by at our place a

couple of days after to clear away all their personal effects such as

equipments, unused raw materials, etc.

The worker was very careful when clearing away heavy stuff.

And he did a very thorough clean-up of our MBR prior to

peeling all the corrugated paper off our floor tiles.

Payment was then collected over weekends after he had

inspected what his team had done for our flat.

An extremely busy but responsible person.

Post-Renovation Advice:

He had also given us post-renovation advice and we are very

grateful for having benefited from his initiatives.

(A) Timing of painting fabricated walls

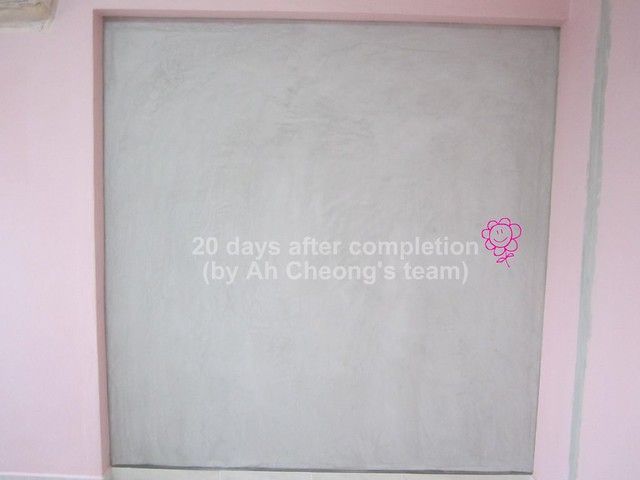

Ah Cheong had strongly recommended that we paint the newly

fabricated walls a month after its completion by Ah Ming. That's if we could spare the waiting time -

we could since it's DIY.

As this would allow the walls more time to "cure"

completely.

I imagined that since it is freshly built, after the water

evaporates from the walls, they would definitely start shrinking abit.

And that is when we will actually know how good the quality

of the fabricated wall is...

(B) How to deal with cracks at the "Joint"

edges

Ah Cheong had assured us that there will be no cracks coming

from the smooth & flat surfaces of the fabricated walls except the edges

where the fabricated walls are "joined" to the existing (HDB) wall

when the wall cures (contraction as most fluid contents would have evaporated

from the walls by then).

We are to use brown silicon (I saw it in hardware shops

& it comes in the form of a brown putty that's used for sealing up cracks

in walls; also shown in NIPPON's online videos) to mend the cracks at the

"joints" prior to repainting it.

http://www.nipponpaint.com.sg/advice/diy-painting-tips-videos/mending-walls

(Post Mortem : There were really fine hair-line cracks at the "joints", which my hubby used an instant putty filler to mend it over with his fingers. This is done at least a few days prior to painting.)

(C) Using an oil-based primer

And he had also given clear instructions that the wall must

be painted with an oil-based sealer prior to a fresh coat of paint, etc etc

etc.

We decided to purchase a 20-litre calibration of NIPPON's

Vinilex 5170 to prime the fabricated walls in the bedrooms, all the rooms &

the ceiling. We are hoping that the

painting would last longer even though the old coats of paint turned patchy

after 8 years of application.

Our verdict for Ah Cheong's services & workmanship is SUPERB & EXCELLENT!

Please do not underestimate the scale of our project posted here becox it involved a great deal of technical skills & connections in getting things right the very first time. And especially we are owners who are still staying in the flat while the reno is on-going AND when our tiling is already in place.

Alot of "gong-fu" is required to do such a brilliant job!

And should we require reno services in the near future, he

would definitely be a top priority in our list of renovators.

This is how one of the fabricated walls & the door frame

looked like now (20 days from completion date of fabricated walls i.e. DAY 23

of reno start date):

[Note: walls in the photos looked distorted becox of the

angle in which they were taken based on natural lighting in the bedrooms. Actual walls were upright & very

straight as seen in earlier photos in this thread.]

There are another 10 more days or so to go before we could

prime it for painting. But we will be

shelfing the painting of these walls further becox we still cannot find time to

DIY painting & many other stuff in our flat yet.

We're also waiting for the "joints" to crack,

which until today, we haven't seen any yet.

So to play safe in ensuring that the wall is further aired dry, we shall

wait beyond 1 month before we start painting.

And this gives us time to stretch our muscles & relax

too!

Meanwhile, I would be starting a new entry on the following so please stay tuned for updates if they do interest you:

Yontat Doors & Hardware Pte Ltd

Sliding Doors & Vanity drawers from Han Fong Aluminium Pte Ltd

Post Mortem : 6 months AFTER the renovation was conducted ...

We've painted one of the bedrooms (MBR) recently before the

Chinese New Year & this is how it looked like with its new image.

Due to the poor lighting in the evening, the room looks

dimmed out.

More photos pending upload

_________________________________________________________________________________

Disclaimer:

Permission has been sought from our contractor, Ah Cheong for his renovation works at my home to be featured in this thread.

Kindly note that this thread is strictly for the purpose of sharing my humble & objective views of works and services provided by the aforesaid contractor.

Reader's discretion is therefore sought when viewing this thread.

In view of issues pertaining to every individual's privacy, facial identities are witheld from the photographs featured in this thread.

Thank you for your kind understanding.

_________________________________________________________________________________

No comments:

Post a Comment